What are halogen-free cables

Halogen-free cables have already been used for many years in different industries. They are applied in public spaces, where people live, work and move. These cables are better than ‘ordinary cables’ when it comes to fire safety, and are less harmful. In this blog we will tell you all you need to know about halogen-free cables. If you’d like to know more, please refer to our free e-book Halogen-free cable compounds.

What are halogens?

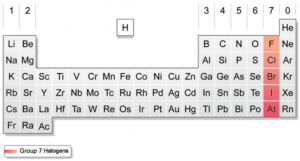

The name halogens refers to five substances. These are non-metal elements in Group 17 of the periodic table. These are the substances fluorine, chlorine, bromine, iodine and astatine. It is a special group of elements we could discuss in detail. We would then talk about electrodes, chemical behaviour and reactivity, but these topics are not important for this blog. What you need to know is that halogens are very harmful to humans. They are even deadly if one is exposed to a certain amount.

The name halogens refers to five substances. These are non-metal elements in Group 17 of the periodic table. These are the substances fluorine, chlorine, bromine, iodine and astatine. It is a special group of elements we could discuss in detail. We would then talk about electrodes, chemical behaviour and reactivity, but these topics are not important for this blog. What you need to know is that halogens are very harmful to humans. They are even deadly if one is exposed to a certain amount.

The introduction of halogen-free cables

Halogen free compounds have been used in a number of applications in the cabling industry since the 1970s. Huge fire events have raised more awareness towards the usage of halogen free compounds in cables. In case of a fire, the halogens that are incorporated into the cable material are released and may be inhaled by people. One of the most striking events was the fire in London Kings Cross tube station. In 1987, 32 people died during this catastrophe. Research showed that the majority of deaths were caused by the toxic gases and by smoke that was inhaled. After this catastrophe, no halogen-containing cables were allowed to be used in the London subway system. As a result, many industries and sectors did not want to use halogen-containing cables any more.

Fire safety and limitation of damage

During a fire, halogen-containing materials emit corrosive and toxic gases. The corrosive gases can damage (electronic) equipment and the like. This was a major focus at communication and data centres and telecommunication organisations. Here, they work with expensive high-tech devices. In 1988, the Bell Telephone Company in Illinois was hit by a fire. In addition to the fact that 35,000 people were unable to make calls, the company suffered a loss of millions of dollars. Their equipment was not destroyed by the fire but was irreparably damaged by the corrosive gases.

The toxic gases are a major hazard in enclosed spaces. Take the example of Kings Cross or, more recently, a similar catastrophe in 2003 in a South Korean subway station where 120 people died. The toxic gases reduce the chance of escape. Upon inhalation, it will quickly affect the human body and result in death.

Halogen-free cables

There is a lot of ambiguity in the terminology as to what constitutes a halogen-free cable. This is because the cable industry does not use one and the same abbreviation or denomination for halogen-free cables. To make this more clear for you, you will find the most common abbreviations in the table below.

| Abbreviation | Meaning |

| LS0H | Low Smoke, Zero Halogen |

| LSZH | Low Smoke, Zero Halogen |

| LSHF | Low Smoke, Halogen Free |

| LSNH | Low Smoke, Non-Halogen |

| NHFR | Non-Halogen, Flame Retardant |

| HFFR | Halogen Free, Flame Retardant |

| FRZH | Fire Retardant, Zero Halogen |

| LSFRZH | Low Smoke, Fire Retardant, Zero Halogen |

‘Low Smoke’ and ‘Zero Halogen’ do not have the same meaning, although many think they do. ‘Low Smoke’ indicates that the cable does not emit a heavy black smoke in case of fire. In case of fire it will only emit thin grey smoke, leaving sufficient view to escape, so the fire is easier to control by the fire department. ‘Zero Halogen’ indicates that there are no halogen substances in the cable. In case of fire, a cable with ‘Zero Halogen’ may still cause heavy black smoke.

Halogen-free materials for cables

There are several halogen-free materials that can be used for cables. These include EVA, Polyamides, EPR, EPDM, PE, PP, SHF1 and SHF2. You can read all about SHF1 and SHF2 in the blog ‘‘SHF1 and SHF2 outer jackets according to NEK 606’. In this blog we will tell you about PE and PP; the other materials are listed in our e-book.

Polyethylene (PE) – has good electrical properties, that is to say that this synthetic material has a good insulating effect. The material is not particularly flexible, but depending on the molecular density it can be made more flexible. When the density is high, PE is a stiff material but stronger and harder than PP. It is moisture-resistant and resistant to low temperatures and ageing.

Polypropylene (PP) – is in many ways similar to PE, especially in terms of electrical properties. PP is tough but more flexible than PE, especially when it is combined with ethylene. PP is used in most cases as insulation material. It is a harder material than PE, so that a thinner insulation layer can be applied.

Want to know more about halogen-free cables?

Receive our eBook and you will find more information about:

- Advantages of halogen-free compounds in plastic materials.

- Halogen-free compounds in cable jackets and insulation.

- Halogen-free cable test standards.