Petrochemical cables in ATEX certified areas

‘Appareils destinés à être utilisés en ATmosphères Explosives’, also known as the ATEX directive, is a European directive describing what equipment and work environment is allowed in a hazardous environment with an explosive atmosphere. It is applicable to petrochemical cables used for ATEX certified installations. The aim of the directive is to allow the free trade of ‘ATEX’ equipment and protective systems within the EU by removing the need for separate testing and documentation for each member state.

The directive is divided into two parts, namely:

- ATEX 95 focuses on equipment and protective systems intended for use in hazardous areas.

- ATEX 137 focuses on the workplace which has to adhere to the minimum requirements for improving safety and health protection of workers in hazardous areas.

Cables in ATEX certified areas and equipments

The ATEX directive does not actually cover cables as such. The construction, dimensions and test requirements of petrochemical cables have to comply with other standards and requirements to ensure that the cables are suitable for hazardous environments. Possible property requirements for cables in such areas are hydrocarbon/chemical resistance, flame retardant, fire resistance, low smoke emission rate, halogen-free, moisture resistance, etc. The major standards in common use are generally fire performance standards. See the table below.

| Test | International standards | Other standards |

| Test for evolution of adidic and corrosive gases |

|

|

| Tests for smoke density |

|

|

| Tests for flame propagation/expansion |

|

– UL1581 – General |

| Tests for fire resistance |

|

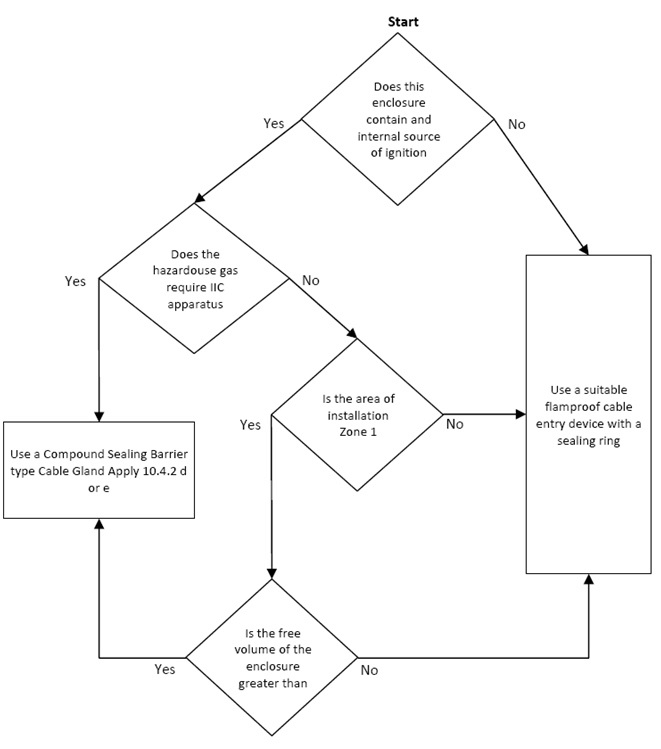

In petrochemical projects, cables are connected to certain equipment and installations by installing a cable gland on the equipment and connecting the cable through the gland. These glands need to comply with the ATEX directive. In the standard IEC60079‐15 a clear cable gland selection chart can be found in order to choose the right gland for the right connection.

More about petrochemical cables?

Receive our eBook you will find the following content:

- Petrochemical processes.

- Petrochemical cable types.

- Type of installation.

- Petrochemical cables in hazardous environments.