Wind turbine cables for wind energy projects

In this blog we will address different kinds of wind turbine cables for wind energy projects. For instance what cables you need to fully operate a wind turbine and which cables are used for transporting the generated power from the wind turbine to the grid. You need to take the location of the wind energy project into account when selecting the right wind turbine cables. Cables for offshore and onshore wind turbines have similarities and differences when it comes to product properties.

Before we go deeper into the wind turbine cables we will focus on the developments in the wind energy market first and show you the most important differences between onshore and offshore windfarms.

Global statistics

Globally, wind power accounts for the largest share of growth in renewables-based energy generation (34%), followed by hydropower (30%) and solar technologies (18%) (IEA, 2014). The annual wind power market grew by 44% and passed 50 GW for the first time in 2014. This results in a higher demand in wind turbine cables. Wind turbine cables for onshore and offshore have similar and different properties.

According to the Global Wind Energy Council (GWEC) total investments in the renewable energy sector reached € 277bn in 2014. The global wind sector saw investments rise 11% to a record € 88.9bn during the same year. This was a significant increased as compared to the 2013 investment of € 71.7bn and the investment of € 72.3bn in 2012.

Cables within a wind turbine

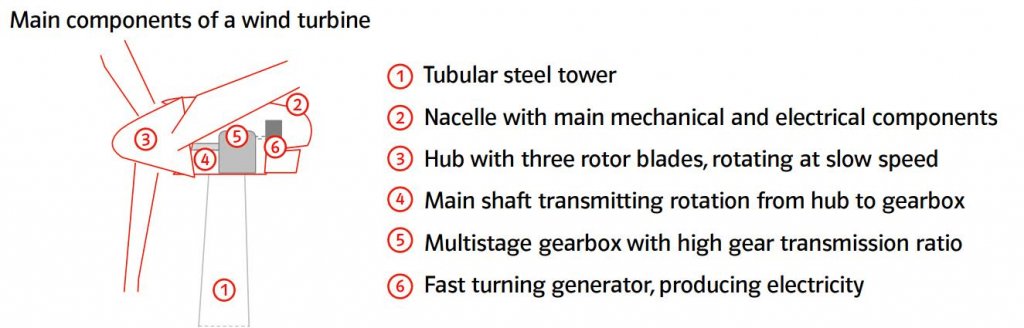

Most wind turbines have a conventional design that is both used in onshore and offshore wind turbines, which includes a gearbox and generator in the nacelle, while “gearless” turbines do not have a gearbox.

Typically two main kinds of cables are used within the nacelle. These include low voltage (LV) and medium-voltage cables. In the nacelle, cables carry low-voltage control signals, data, and communication signals. Other cables carry power down from the generator and are used to switch gear at the tower base.

Low voltage and medium voltage wind turbine cables

The LV/MV cables are generally designed for flexible applications and thus require a good bending radius. The reason for the flexibility is that power cables from the generator drop a couple meters below the nacelle that lets the nacelle turn without winding or stressing the cable. These cables should be able to withstand extreme high/low temperatures are therefore usually required to have a special rubber insulation and sheath or compounds with similar physical performances.

The systems within the turbines also require sophisticated control, electronic and data transmission cables, and fibre optic cables to help manage them.

Controls cables are flexible, mainly shielded (to prevent electromagnetic interference) and are used to carry small currents and low frequency signals that are used to control the motor drive, the generator’s braking system, the nacelle’s positioning and the optimizing of rotor speeds.

Electronic and data transmission cables are used to control all electronic and mechanical devices. They are used to measure wind speed, temperature and performance parameters. Increasingly, all cables are electromagnetically (EMC) shielded.

Fibre optic cables are used to assure high data transmission capacity for monitoring and control.

Properties of wind turbine cables

Wind turbine cables in nacelles should also be oil-resistant because of occasional exposure to hydraulic oil, and more likely, exposure to gearbox oil. Insulation can harden or swell with exposure to lubricants and expose conductors with sufficient wear.

Other properties for wind cables are: abrasion-, UV- and ozone-resistant and resistance to temperatures ranging from -40°C up to 90°C. Increasingly, there has been a demand for LS0H (Low Smoke halogen free) material for the insulation and sheath in case of fire.

Onshore and offshore windfarm conditions: differences

Wind turbine cables have a vital role in delivering energy generated by wind turbines. Wind turbines exist of a nacelle, tower and base. Cables which are used include power transmission and distribution as well as control, electronic, data transmission and fibre optic cables.

Onshore and offshore wind conditions are not the same. The flow of onshore wind faces obstacles such as landscapes, trees and buildings, which distort the flow of the wind. In contrast, offshore wind flows without obstacles and with higher wind speeds.

Other main differences between onshore wind and offshore wind can be found in the table below.

| Onshore wind turbines | Offshore wind turbines | |

| Resources |

|

|

| Dimensions |

|

|

| Environment |

|

|

| Foundations |

|

|

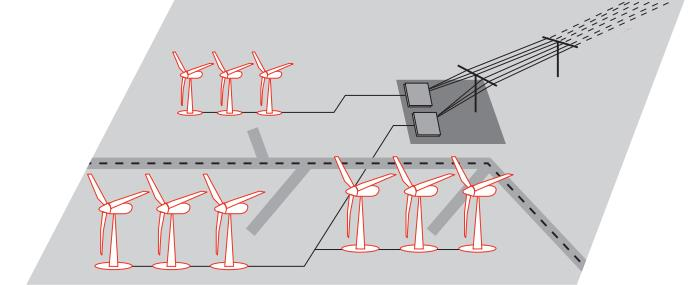

Onshore wind farms

On onshore wind sites, wind turbines are usually clustered into rows. These turbines are then connected to each other with inter-array cables which transport the electricity from the wind turbine to the substation or the grid. The energy is transported to substations where the voltage is increased to reduce transmission losses by using transformers. The electricity is then transported through export lines.

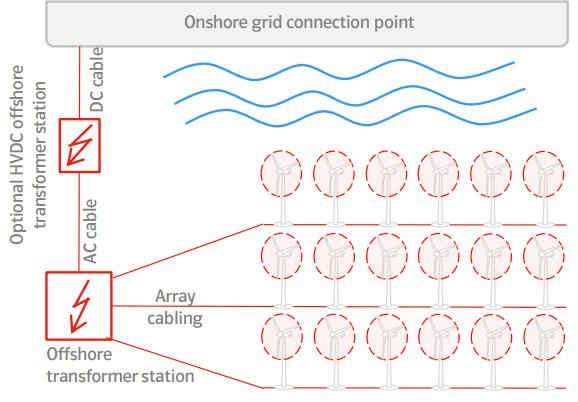

Offshore wind farms

Within the offshore wind farm, array cabling (AC) connects rows of wind turbines to the offshore transformer station. The offshore sea-cable (AC or DC) connects the offshore transformer station to the onshore grid. For larger distances from shore, High Voltage DC (HVDC) transformer stations are used to transmit the electricity via DC cables to the shore. For safe operations, offshore cables are buried up to three meters deep into the seabed.

More about cables in the renewable industry?

Receive our eBook you can find the following content:

- Renewable energy sources.

- Wind power generation cables.

- Solar power generation cables.

References

E.ON (2012), Offshore Wind Energy Factbook.

E.ON (2013), Wind Turbine Technology and Operations Factbook.

International Energy Agency – IEA (2014). World Energy Outlook